We’re committed to helping you.

855-707-PROS (7767)

Call the Pros!

Vibration Analysis

Pros, Inc. Services

Infrared Thermography

Web-Based Reporting Software

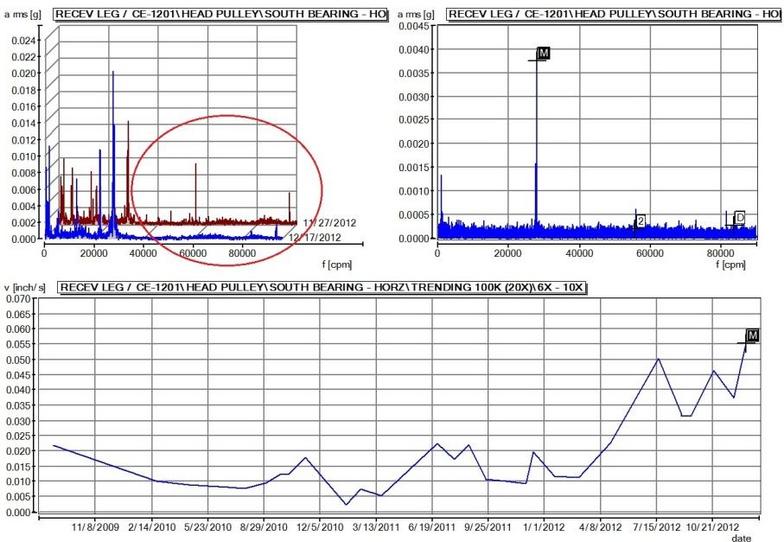

Pros, Inc. believes in improving the reliability programs of each one of our clients so that they can avoid costly downs and focus their resources elsewhere. To do so, we specialize in offering comprehensive technologies for a successful reliability program. The cornerstone of a great reliability program lies in vibration analysis.

We use cutting-edge technology to provide excellence in creating and implementing your Equipment Vibration Analysis Program (EVAP) as well as offering vibration analysis consulting whenever needed. This includes being available to you 24/7 for emergency call-out situations.

At Pros, Inc., we want each of our clients to reach the peak of their potential by optimizing their production and reliability. As a company, our goal is to always be on the forefront of predictive maintenance and reliability solutions, always making time for research and learning, then sharing that information with you. That is how we provide you with the most current, most efficient predictive maintenance knowledge.

By taking a proactive approach to maintenance you will avoid costly downs and improve your asset health, run more efficiently, and get longer life from your equipment. In addition to normally scheduled service we are available for emergency call-outs 24 hours a day, 7 days a week. Our team members are professional, knowledgeable, and efficient.

We provide a comprehensive offering of reliability services including the following:

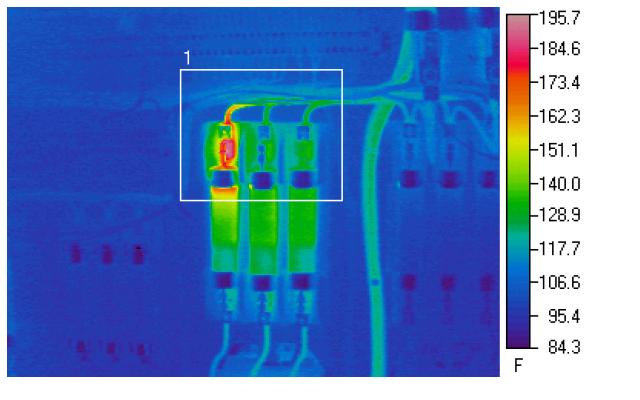

With Infrared Thermography inspections, Pros, Inc. can take an image and learn of thermal variance which gives us the capability of seeing problems that could cost thousands of dollars in repairs and down time if they had gone undetected.

Through the use of Infrared Cameras, our team can identify electrical, mechanical and structural faults. We strive to provide the most accurate observations through the use of the high resolution images we capture and consult with your staff to provide analysis, make recommendations for repairs, and provide valuable technical support throughout the process.

Pros, Inc. is proud to utilize secure, web-based reliability reporting.

This web-based reporting offers an encrypted, authenticated web portal to your reliability reports. You will have a password protected login, multiple user access to your specific plant or locations, and access to multiple technologies on one page. Access your vibration analysis reports, infrared inspection reports, ultrasonic inspection reports, oil analysis reports, and more.

With this software, you can access reports and analysis within hours of completion. You get clear notification of what equipment needs attention with highly visible alerts on your home page. That way, you know what to repair when, allowing you to find great cost savings by planning your maintenance efficiently and avoiding costly downs.

If you have any questions regarding reliability services or prices, please don't hesitate to contact us. Our friendly customer service staff will help find the best solutions for you. We can be reached at

855-707-7767 (PROS), ext. 326.

Ultrasonic Inspections

Maintaining the health of your assets requires a disciplined approach in your maintenance program, especially in instances where industrial compressed air systems are utilized. Leaks in compressed air systems can waste up to 30% of a compressor’s output, according to the Department of Energy. Proactive leak detection and repair can minimize wasted energy and control other operating losses.

The use of our Ultrasonic Inspection services can stabilize system pressure by testing for compressed air leaks as well as pressure and vacuum leaks. Our services can be used to test valves and valve stems, reciprocating compressor valves, seals and gaskets, hatch leaks, flanges, fittings and more. By utilizing a program of leak inspection and repair, your facility will function more efficiently, thus reducing the amount of energy used. This reduction in energy used will lead to significant cost savings and reduced carbon emissions. In addition, by running healthier equipment, it will wear slower, lengthening the lifespan of your equipment and decrease costly, unscheduled downtime.

To meet the ultrasonic needs of our clients, we offer steam-trap inspections, air leak inspections, and ultrasonic thickness testing.

Dynamic In-Place Balancing

Imbalance is an issue commonly found through vibration analysis and visual inspections. It can be costly to do if you have to balance components offsite. That is why we offer dynamic in-place balancing. It allows for quick and easy balancing so that your equipment can function as needed. This consulting service can greatly reduce energy costs (sometimes up to 2 to 3%!), extend the life of your equipment, improve production, and is an easy way to avoid unnecessary equipment repairs and replacement.

Training & PdM Audits

We want to see you develop a world-class Reliability Program. The core values of a successful program are a disciplined approach, a precise development of the database of equipment to be monitored, and the appropriate frequency of inspection. We start with an initial questionnaire establishing an accurate assessment of your current reliability strategy. We follow that with a complete and thorough analysis of your PdM protocols and procedures.

We will then provide the most accurate observations and concise recommendations for an improved reliability program. By utilizing Pros, Inc. to train your staff or audit your current program, our recommendations for how to continuously monitor your equipment will greatly enhance the management of your maintenance activities and performance of your work flow process.

Electrical Infrared Thermography Image

Vibration Analysis Trend & Spectrum

Team Training & PdM Audits

Reliability Engineer Taking Vibration Readings